Comprehensive Information on hard gelatin capsule

This article describes about hard gelatin capsule manufacturing and filling operations different usage of utilized line machine during filling operation and troubleshooting during process.

Comprehensive Information guide on hard gelatin capsule

INTRODUCTION :

In 18th century Mothes and Dublanc two Frenchmen are credited for invention of single piece gelatin capsule, while James Murdock of London invented the two-piece telescoping capsule later on. The single piece, olive-shaped gelatin capsules were produced by dipping two metal rods into a warm gelatin solution and then letting the capsules dry before filling them with medicine. The capsule was then sealed with a drop of gelatin solution

The two-piece telescoping capsule, on the other hand, consists of two separate parts that fit together perfectly to enclose the medicine. The lower part of the capsule, called the body, is filled with the medicine, and then the upper part, called the cap, is fitted onto the body to enclose the medicine completely.

Both types of capsules have been widely used in the pharmaceutical industry for more than a century, as they provide a convenient and easy-to-swallow way to take medication.

Definition Of hard Gelatin Capsule :

A hard gelatin capsule is a type of oral dosage form that is commonly used to administer solid, powdered, or pellet medications. It consists of two distinct parts, a lower body or “cap” and an upper body or “body,” that are made of two pieces of hard gelatin that fit together.

The hard gelatin capsule shell is typically composed of gelatin, water, and a plasticizer, and it can be transparent or opaque, depending on the intended use.

The contents of the hard gelatin capsules are usually in a solid or powder form and are placed inside the hard gelatin capsule shell before the two halves are sealed together. Hard gelatin capsules are often preferred by patients due to their ease of swallowing and ability to mask unpleasant tastes or odors of the medication.

Classification of Capsule :

Different types of capsule can be classified as:

1. Hard capsules

Hard Capsule :

Hard gelatin capsules have shells consisting of two prefabricated cylindrical sections with hemispherical ends. One end of which is rounded and closed, the other being open.

The active substance(s) usually in solid form (Powder/granules/pellets/Tablets) are filled into one of the sections, which are then closed by slipping the other section over it. The security of the closure may be strengthened by suitable means.

Soft Capsules :

Soft gelatin capsules have thicker shells than those of hard capsules. The shells consist of one singular part and are of various shapes.

Soft gelatin capsules are usually formed, filled and sealed in one operation but for extemporaneous use, the shell may be prefabricated. The shell material may contain an active substance.

Liquids may be enclosed directly; solids are usually dissolved or dispersed in a suitable vehicle to make a solution or dispersion of a paste-like consistency.

There may be partial migration of the constituents from the capsule contents into the shell and vice versa because of the nature of the materials and the surfaces in contact.

In other words soft capsule is a solid pharmaceutical dosage from where the gelatin shell is plasticized by addition of polyhydric alcohol eg: glycerol to render the shell elastic and after filling the contents within the shell. The two shells are heat sealed to produce a longitudinal shape in the final product.

Advantages of Hard Gelatin Capsule :

- Easy to swallow: Hard gelatin capsules are easy to swallow because they have a smooth and slippery surface, making them ideal for people who have difficulty to swallowing tablets or pills.

- Versatility: Hard gelatin capsules can be filled with a wide range of materials, including powders, liquids, semi-solids, and even small objects such as beads or pellets.

- Protection: Hard gelatin capsules provide a protective barrier around the active ingredients, helping to prevent degradation due to moisture, light, or air.

- Customization: Hard gelatin capsules can be customized in terms of size, shape, and color, allowing for branding and easy identification of different products.

- Bioavailability: Hard gelatin capsules are designed to dissolve quickly in the stomach, releasing the active ingredients for rapid absorption into the bloodstream, which can increase their bioavailability compared to other forms of medication

- Tamper-evident: Hard gelatin capsules can be designed to be tamper-evident, providing an added level of security to the enclosed substance.

- Taste and odor masking: Hard gelatin capsules can be formulated to mask the taste and odor of the enclosed substances, making them more palatable and easier to swallow.

- Low production cost: Hard gelatin capsules have a low production cost compared to other forms of drug delivery, such as tablets or soft gelatin capsules.

Sizes of hard gelatin capsule:

Hard gelatin Capsules are of different sizes, which are ranging from Size “000” to “5”. Size “00” to Size “5” are generally intended for human use.

Size “000” is used for veterinary purpose.

Note : Hard gelatin Capsules are made principally of gelatin blends and may contain small amount of certified dyes, opacifying agents, plasticizers and preservatives.

Hard Gelatin Capsule Manufacturing and Filling:

Process of hard gelatin capsule manufacturing is divided into two parts.

- Manufacturing

- Capsule Filling

Manufacturing:

The blend, which is to be filled in the hard gelatin capsule, is prepared by either wet granulation or dry granulation method, 90-95% formulations are prepared by direct mixing method. All the manufacturing have to be carried out under the controlled environmental conditions i.e. Temperature and Relative Humidity throughout the process is (19-25°C) and (45 to 55% % RH.) Respectively

Image I : Process Flow Chart For Manufacturing

Hard gelatin Capsule Filling:

Filling is the process of enclosing of drug (Powder, pellets, granules, Tablets or combinations) in the Empty Hard Gelatin Shells. The principle of Filling varies from machine to machine and product to product also. The Various principles of Filling are:

- Tamping Principle.

- Dosing Principle.

Filling is the most critical process of hard gelatin Capsule Manufacturing as it gives product identification, dosing of drug and protection of drug enclosed in it. The various Automatic hard gelatin capsules Filling Machines available in market for which filling speed varies from 0.25 Lac – to 2.0 Lac Capsule filling per Hour.

Image I : Process Flow Chart For Capsule Filling

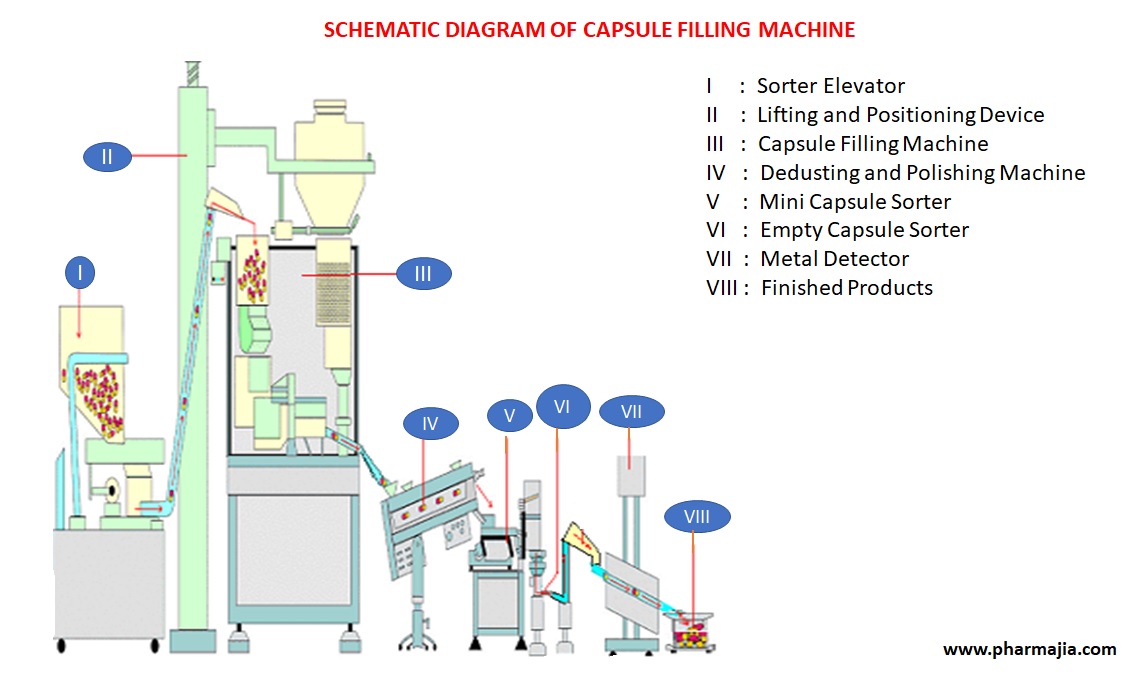

Along with the Filling Machines, Line Machines also installed in the line for the related functions like Dedusting and Polishing, sorting of diametrical rejects, short capsules, sorting of empty capsules, metal detection etc.

Image I : Schematic Diagram of hard gelatin Capsule Filling Machine

Line Machine for Automatic Capsule Filling Machine :

- Empty Capsule Sorter Elevator.

- Dedusting and Polishing Machine.

- Mini Capsule Sorter.

- Empty Capsule Sorter

- Metal Detector.

Empty Capsule Sorter Elevator :

The Machine does the dual function of

- Sorting out diametrically defective hard gelatin capsules from good ones.

- Conveying good quality empty hard gelatin capsules to the hopper of the capsule filling machine.

The machine also avoids operator fatigue due to automatic loading.

By sorting out defective capsules, the Machine ensures a continuous and smooth flow of good quality capsules to the capsule filling machine.

Operation principle :

The Machine works on the principle of air lifting of empty capsules.

The EHG capsules are stored in the capsule hopper of the machine. As and when the level of capsules in the Capsule Filling Machine hopper falls below a predetermined level, the machine starts loading the empty capsules to the hopper and stops when the set level is reached.

The hard gelatin capsules are delivered from the Hopper to Feeding Tray, from where they move forward on to the Sorting Plate. The forward movement of the hard gelatin capsules is due to the vibratory motion of the Feeding Tray. The flow of hard gelatin capsules from the Feeding Tray to the Sorting Plate can be regulated with the help of Gate mounted on the Hopper.

The hard gelatin capsules are sorted in the sorting section before they are conveyed to the Capsule filling machine. The sending of hard gelatin capsule level in the Capsule filling machine is done with the help of two sensors mounted on the Capsule filling machine hopper. One is for low level sensing and the other is for high level sensing.

The air stream required for lifting the hard gelatin capsules is developed by an Air Blower.

Dedusting and Polishing for filled hard gelatin capsule :

Dedusting and Polishing Machine is used to remove the powder, which gets deposited on the capsule surface.

Operation principle :

The machine uses the rotating spiral nylon brush concept to clean the hard gelatin capsule on a continuous basis.

Hard gelatin capsules are fed into a cylindrical chamber (polishing chamber) where a rotating spiral brush removes the powder particles sticking to the outer surface of hard gelatin capsules and at the same time transports the hard gelatin capsules forward.

A vacuum suction port, the suction side of which is used for cleaning purpose is to be used to suck the dedusted particles on a continuous basis.

As the hard gelatin capsules are fed into the polishing chamber from the infeed hopper, the spiral brush pushes the capsules towards the delivery chute against the force of gravity. During this process, the capsules undergo a rubbing action against the nylon bristles and surface powder gets removed and is sucked by the vacuum port. The continuous rubbing of capsules against the rotating brush ensures complete polishing of the capsules.

Mini Filled hard gelatin Capsule Sorter :

The hard gelatin capsule Sorting Machine (Mini Filled Capsule Sorter) carries out automatic diametrical sorting of filled capsules.

The Machine is designed to sort out capsule defects like:-

- Loose cap/ body

- Telescoped capsule

- Pinched capsule, Notched capsule and Broken capsule

- Diametrically oversize or oval capsule

By sorting the hard gelatin capsules on the Mini capsule sorter Machine, majority the defective capsules gets sorted out automatically.

Operation principle :

The Machine is basically divided into two sections viz.,

Loose cap/ body sorting section : Plate Sorter

Diametrically defective capsule sorting section : Drum Sorter

-

Loose cap sorting section : Plate Sorter

In this sorting section, caps from the unjointed capsules are sorted out.

The movement of the capsules in the loose cap sorting section is due to the vibratory motion. This section is mounted on electromagnetic vibrator, which imparts the vibratory motion.

The sorting section is so designed; that the loose caps coming along with the filled capsules fall through the holes in the Sorting Plate as the capsules move forward along the Plate. These caps get collected in the defective Capsule Collection Box. The rest of the capsules move forward.

This sorting section also removes loose powder coming out from the machine.

-

Diametrically defective hard gelatin capsule sorting section : Drum Sorter

This section consists of a Drum Sorter with sorting plates specific size and configuration. The geometry of the holes is so designed that the hard gelatin capsules which are diametrically defective or oversize and which will affect further processing like packaging etc. get sorted out. These hard gelatin capsules get trapped in the holes of the Sorting Plate of Drum Sorter, while the good capsules pass through to empty capsule sorter. The clogged hard gelatin capsules can be removed manually at regular intervals, which get collected in a defects collection tray.

The sorting in the Drum Sorter takes place by rotating the Drum through a motor, timer belt and pulley arrangement.

Empty hard capsule Sorter :

Once the hard gelatin capsules are closed, it becomes very difficult to identify the empty capsules among filled capsules, unless physically weighed.

The Empty Capsule Sorting Unit is designed for automatic sorting of empty capsules, loose caps and loose bodies from the filled capsules.

The machine can be used in line with the Capsule Polishing Machine or can be used along with any other machine, which ensures uniform carpet flow of capsules.

A) Principle of Operation :

The machine employs the principle, that lighter objects float on an air stream, and these objects can be lifted up by increasing the air stream velocity. By varying the air stream velocity, the objects of various weights can be lifted.

The filled hard gelatin capsules are fed uniformly in a carpet form in the funnel type capsule hopper and then they enter the hopper tube. The capsules flow into the sorting chamber and get exposed to the cyclonic, upward moving air stream.

The filled hard gelatin capsules being heavier, reach to the bottom of the sorting chamber and come out from the bottom outlet, as they are not getting lifted by the cyclonic air draft. The empty capsules being lighter, are lifted upwards and are arrested by the capsule deflector mounted under the funnel type hopper and get delivered from the top outlet to the empty capsule collection box.

To facilitate sorting of various sizes of hard gelatin capsules, provision is made to adjust the air flow rate.

Metal Detector :

Metal Detector is used for detecting metal particles (ferrous/non-ferrous/S.S.) in filled capsules.

Operation principle :

The principle of operation is used for this model of metal detector is ‘Eddy Current Principle’.

Capsules which cause a change in electromagnetic field due to metal particle contamination are deflected and rejected out of the system.

Various Inprocess Tests during manufacturing and hard gelatin capsule Filling Operation :

The various Inprocess checks used in hard gelatin capsule manufacturing and filling

Inprocess Test During Manufacturing :

(1) LOD (loss on drying)

(2) Tapped density

(3) Percentage fine.

LOD (loss on drying) :

This is a quantitative method of determining the loss in weight of material due to heat by drying process.

Tapped Density :

This is mainly used to determine the consolidation index of the powder

Percentage Fines :

This is mainly used to evaluate the available fines and Granules percentage in powder

Inprocess Test During hard gelatin Capsule Filling :

(1) Group weight.

(2) Individual weight variation.

(3) Lock length of capsule.

(4) Uniformity of Mass.

(5) Capsule Appearance checks.

(6) Disintegration Test.

Group Weight Variation :

In this method weight of 10 or 20 hard gelatin capsules can be taken at every predetermined time of interval.

Individual Weight Variation Test :

In this test weight of 30 or 40 hard gelatin capsules can be taken individually at every predetermined time of interval

Uniformity of Mass :

In this test weight of 30 or 40 hard gelatin capsules can be taken individually at every predetermined time of interval

Lock Length :

The lock length of hard gelatin capsule of one station is checked at every predetermined time of interval

Capsule Appearance checks :

The bulk finished hard gelatin capsules are checked manually for any defects at every predetermined time of interval.

Disintegration Test :

The bulk finished hard gelatin capsules are checked for disintegration time every four hours at at every predetermined time of interval.

Instruments Used in IPQC :

(1) IR Moisture Analyser.- Used for checking the LOD Test for Powder/Granules

(2) Tap density tester : Used For checking of Tap density for powder/Granules

(3) Weighing Balance : Used to check the Group/Individual weight of filled capsules

(4) Vernier Caliper : Used to check Lock Length of Capsules.

(6) Disintegration Test Apparatus : Used to check the Disintegration Test of capsules.

JOB RESPONSIBILITIES :

Machine Operator :

- Daily maintenance of machine.

- Machine and area cleaning as per SOP for product to product and batch to batch changeover.

- Machine setting as per SOP.

- Machine operating with minimum rejections and maximum outputs, maintaining quality standards within the standard norms.

- In process checks and recording on batch record.

- Operating and down time recording on machine log.

- In process parameter checking.

- Cleanliness checking of equipment and utensils used in process and fixing of status label with signature.

- Maintenance of area cleanliness.

- Reporting any problem in the machine with suggestions.

- Regular maintenance of documents.

- Reporting every problem arising in the use of material and the product.

- Taking safety precautions during working on the machine.

- Maintenance of dosing parts and other change parts.

Production Officer/Executive :

- To follow the GMP and SOP, any deviation should be approved by QA

- To maintain discipline in the department.

- To maintain the filling machines, dosing parts, change parts and its inventory.

- Checking of status labels at all stages of manufacturing.

- Training of Workmen and Machine Engineers.

- Discussion of the problem faced on the day with Department Incharge.

- Validation of product process and cleaning process in co-ordination with Q.A. and Q.C.

- Calibration of equipments as per the schedule.

- Raising of Test information sheet for Product process validation and Cleaning validation of equipments.

- Monitoring the temperature, relative humidity and pressure differential record of the area.

- Monitoring the sanitation record.

- On line in process checks and recording in batch record.

- Supervision of area and co-ordination with other departments.

- Control on daily Production output.

- Monitoring the Fly-O-Cide count record.

- Taking safety precautions during working on the machine.

Safety :

Safety checks/Precautions to be taken in capsule Manufacturing/Filling area :

- While entering the cubicles, personnel must wear snood.

- Fire extinguishers in filling corridor must not be obstructed and must be easily approachable.

- Snood and latex hand gloves must be used while handling the product on the machine.

- The electrical wiring of the filling machines must be well insulated.

- All machines should have earthing connectivity properly.

- Compressed air pressure should be 6-7 Kg. / sq. cm. or as per the machine requirement.

- Before starting operation check whether all safety guards and limit switches of the machine are functioning properly.

- Before switching ‘ON’ the machine ensure free movement of all moving parts by manually rotating the hand wheel

- During trial run of the machine after setting, first run the machine at slow speed for about 1 minute and then gradually increase the speed to maximum.

- Moving parts of the machine should not be touched.

- If any unusual sound or vibration is observed stop the machine and inform department head and maintenance department.

- Working of safety guards and limit switches must be ensured regularly.

- Steam line, compressed airline, potable waterline must be checked for leakage before starting operation.

- Compressed air must not be used to clean clothes or any other part of the body.

Problems and Remedies for Hard gelatin capsule :

Failure to operate the machine as directed is a malfunction. Probable causes and suggested remedies of major and frequent problems are listed below:

Related To Machine :

| Problem | Probable cause | Suggested Remedy |

| The machine does not start in ‘Manual mode’ |

Handwheel in manual position Air compressor not connected / low air pressure hard gelatin Capsule level is low. Powder is not sensed by the proximity switch The proximity switch does not sense pellets. Emergency push buttons is pressed. |

Pull the locking latch up and pull the handwheel out. Connect air compressor. Adjust pressure regulator setting as per the capsule filling machine requirement. Fill the hard gelatin capsules in the capsule hopper. Fill the powder in the powder hopper. Fill the pellets in the pellet hopper or delete “pellet” programme on PLC. Rotate the red knob clockwise and the emergency push button will disengage. |

| The Machine does not start in ‘auto mode’ |

Safety doors are open Selector keys not in ‘auto mode’ |

Close all the safety doors.

Put selector key, Door Safety to “On” and Powder feed to “Auto” modes. |

| The Machine does not speed up | Speed set potentiometer at low speed setting.

Potentiometer not functioning

Controller of variable speed drive malfunctioning. |

Turn the potentiometer knob clockwise gradually

Repair or replace the potentiometer

Repair or replace the Controller |

Feeding & Opening :

| Problem | Probable cause | Suggested Remedy |

| Hard gelatin Capsule does not enter in Magazine hole | Wrong size of hard gelatin capsules.

Damaged capsule blocking the magazine hole.

Incorrect setting of baffle. |

Remove any wrong size of hard gelatin capsules.

Remove damaged hard gelatin capsule with nylon wire

Set baffle plate properly. |

| More than one hard gelatin capsule falls in the rectifier slot. | Spring gates are damaged.

Incorrect setting of spring gate actuator. |

Fit new spring gates.

Set the position of spring gate actuator correctly. |

| Ejection of damaged capsule from rectifier block | Incorrect setting of horizontal blade assembly.

Incorrect setting of vertical blade assembly.

Distorted / damaged capsules stuck in the rectifier raceway.

Rectifier raceway worn out. |

Set horizontal blade assembly position correctly.

Set the position of vertical blade assembly correctly.

Remove distorted / damaged capsule from the rectifier raceway

Replace rectifier raceway. |

| Cap falling

out of cap bush during transfer |

Improper vacuum setting.

The gap between cap bush and body bush is more than 0.2 mm

Cap bushes are not aligned with body bushes. |

Reduce the amount of vacuum by partly closing the valve.

Adjust the gap to 0.05 – 0.2 mm

Align the holes of cap bush holder plate and body bush holder plate. |

| hard gelatin Capsule do not enter the cap bush clearly or fail to open

|

Broken capsule pieces in cap bush.

Misalignment between cap and body bushes.

Powder accumulated in the bushes.

Broken hard gelatin capsule pieces block the vacuum opening. |

Remove broken hard gelatin capsule pieces.

Align the cap bush holder plate with body bush holder plate.

Clean the bushes with nylon brush and vacuum. If powder remains, then remove the bushes and wash in warm water.

Remove broken hard gelatin capsule pieces and clear vacuum openings.

|

| Cap falling out of cap bush during transfer | Improper vacuum setting.

The gap between cap bush and body bush is more than 0.2 mm

Cap bushes are not aligned with body bushes.

|

Reduce the amount of vacuum by partly closing the valve.

Adjust the gap to 0.05 – 0.2 mm

Align the holes of cap bush holder plate and body bush holder plate.

|

| hard gelatin Capsule do not enter the cap bush clearly or fail to open

|

Broken capsule pieces in cap bush.

Misalignment between cap and body bushes.

Powder accumulated in the bushes.

Broken capsule pieces block the vacuum opening.

Cap and body bush plates do not come close together at the capsule opening station

Worn out cap and body bushes

|

Remove broken capsule pieces.

Align the cap bush holder plate with body bush holder plate.

Clean the bushes with nylon brush and vacuum. If powder remains, then remove the bushes and wash as per SOP.

Remove broken capsule pieces and clear vacuum openings.

Check air pressure and check cap and body bush plate settings.

Replace |

| vi) Lower part of capsule body broken off or damaged | Excessive vacuum

Sharp edges in the body bush |

Reduce vacuum

Replace bush |

Note : Correct capsule dimensions is a critical requirement for proper rectification, loading and opening of empty capsules of automatic capsule filling machine. Capsule can loose their original dimensions due to excessive heat or moisture. Such capsules will be distorted, fused or shrunk and will not work satisfactorily on the filling machine. Exposure to low humidity can also cause capsules to become brittle. Such capsules will crack or break with the application of vacuum or when closing after filling powder.

Related to Powder Filling :

The flow property and compressibility of the powder formulation are the most critical factors for UNIFORM FILL WEIGHT.

| Problem | Probable cause | Suggested Remedy |

| Weight variation | Slug not properly formed.

(Formulation needs to be adjusted)

Incorrect alignment between dosing disc and body bushes.

Tamping pin springs are worn out or broken.

Dosing disc damaged or worn out.

Insufficient powder in tub.

Improper setting of tamping pins.

Improper gap between dosing disc and support disc. |

Correct the Formulation

Correct the alignment

Replace with a new set of springs.

Replace dosing disc.

Ensure enough powder.

Set tamping pins.

Adjust the gap in between 0.05 – 0.1mm maximum.

|

Related to Filled Capsule Closing & Ejection :

| Problem | Probable cause | Suggested Remedy |

| The capsule is telescoped or dented | Powder adhering to body

bushes.

The gap between capsule closing plate and cap dome is incorrect

Incorrect alignment of cap and body bushes.

Incorrect centering of closing pins.

Bent closing pins

Cap bushes are worn out

Capsules have rough edges

|

Clean the body bushes with brush and vacuum.

Set closing plate properly. Align cap bush holder plate with body bush holder plate.

Correct alignment

Replace.

Replace.

Replace.

Check and remove defective capsules.

|

| Capsule does not lock or partially locks | Excess volume of powder prevents proper closing.

Incorrect closed length setting.

Excessive closing of capsules causes closed length variation. |

Increase compression to form smaller length of slug.

Adjust the closed length setting

Set the closed length as per the recommendations of empty capsule manufacturer. |