Difference Between F0 and Fh Value

| F0 Value | Fh Value |

| It is equivalent Exposure Time | It is heat Penetration factor |

| Assess the effectiveness of Steam Sterilization | Assess the effectiveness of Dry Heat Sterilization |

| The assumed z-value is 10°C for sterilization range of 100 to 130°C | The assumed z-value is 20°C for sterilization range of 160 to 200°C |

| Theoretical Requirement 121.1°C at 30 min. of sterile hold time |

Theoretical Requirement 170°C at 32 min. of sterile hold time |

| Mitigates micro-organisms, especially living endospores | Removes bacterial endotoxins |

What is mean by Dry Heat Sterilization (DHS) ?

Working Principle :

Dry heat sterilization uses conduction as a mode of heat transfer. The heat is absorbed by the outside surface of an item, then passes towards its inside center. It will eventually reach the temperature required for sterilization.

In other words, the dry heat oxidizes the cell contents and thereby kills the organisms.

A blend of temperature and time is required to kill microorganisms by heat. In general, an increase in temperature will result in a decreased time for bacteria-kill.

Items that can withstand high temperatures can be sterilized with Dry Heat sterilization like anhydrous (moisture-less).

Uses of DHS:

Dry heat sterilization is particularly suitable for materials that can tolerate high temperatures and are damaged by moisture or high pressure.

Since dry heat does not cause corrosion of metal instruments and glassware, it is appropriate for sterilizing them, but it can’t be used to sterilize fabrics, plastics, or rubber.

Lastly, DHS is for materials that must remain dry. For example, glass bottles that contain pharmaceutical powders.

There are two types of dry heat sterilization:

-

Natural Convection

-

Forced Convection

Differences of these two systems as Tabulated Below :

| Natural Air Dry heat sterilization (DHS) | Forced Air Dry heat sterilization (DHS) |

| Oven-type coils transfer the heat from the bottom of the chamber by gravity convection. | Blower-driven system circulating hot air across the chamber at high velocity. |

| More of a traditional setup. | An advanced setup. |

| Requires more time to attain the sterilization set temperatures. | The rate of convection is high due to the use of a blower. Hence achieves the sterilization set temperature in a quick time. |

| Inconsistent temperature distribution inside the chamber. | Uniform temperature distribution across the chamber. |

What is mean by Depyrogenation ?

The process that removes or inactivates the pyrogens (disables their multiplication) is called depyrogenation.

In aseptic filling, depyrogenation is mainly utilized for sterilizing vials. It can also be used for sterilizing assembled and packaged materials, as heat conduction is not dependent on contact with steam or water.

In Depyrogenation case, the temperature is even more than DHS and the Fh value is then replaced by the Fd value.

Fd value is a function to measure the effect of the depyrogenation. If we say Fd value to be 3, the effect achieved is equivalent to the exposure of 250°C at 3 mins.

Meaning, as F0 value is for Steam Sterilization, Fd value is for Depyrogenation.

The theoretical requirement for Depyrogenation is 250°C at 30 min. with the z-value assumed as 46.4°C . Though this is an ideal condition, a successful depyrogenation would also establish when the system achieves ≥ 3 log reduction.

Whereas, Dry Heat Sterilization occurs at 170°C for 32 min.

Parameter Comparison for Dry Heat sterilization and Depyrogenation

| Parameter | Dry Heat Sterilization | Depyrogenation |

| Value | Fh value | Fd value |

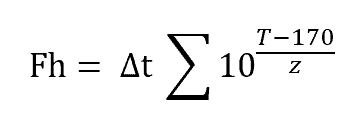

| Formula difference | T -(minus) 170°C | T-250°C |

| z-Value | z = 20°C | z = 46.4°C |