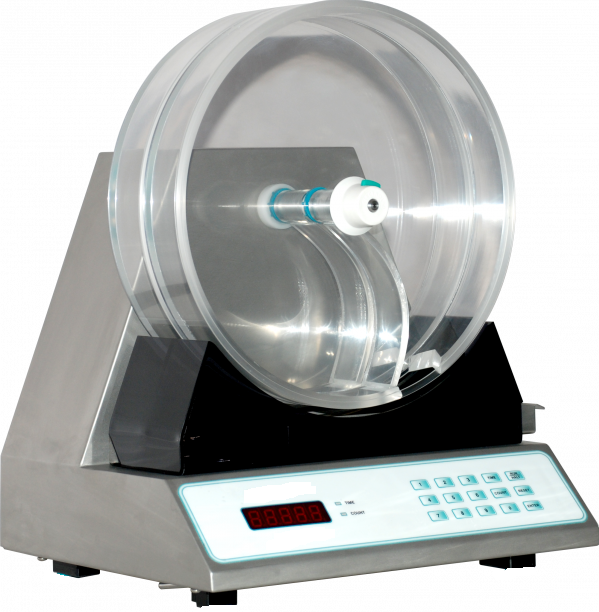

Operation & Calibration of Friability test apparatus

This article contains Operation and Calibration of Friability test apparatus.

Operation & Calibration of Friability test apparatus

What is mean By Friability Test ?

Why Friability Test is important as a in process checks in Tablet Formulations ?

The friability test provides a measure of the tablet’s strength, and resistance to abrasion. It helps to detect any defects in the tablet formulation, such as insufficient binding agent or improper compression force, which can lead to tablet breakage, crumbling or disintegration. The test also ensures that the tablets can withstand the rigors of transportation and handling, and will not break down into pieces and will not be chipped during shipping or storage.

By performing the friability test as an in-process check during tablet manufacturing, it can help prevent costly recalls or rejections of batches, which could result in wasted time, materials, and resources. Therefore, the friability test is an important quality control measure that helps to ensure the consistency, stability, and quality of tablet formulations.

How much sample Quantity to be taken For friability Test as per IP/BP/USP-1216/EP2.9.7.

Note : Friability should be performed for 100 Rotation i.e. 25 Rotations/Minute

Procedure for performing Friability Testing

Test procedure: Dedust the tablets carefully and weight accurately the required number of tablets. Place the tablets in drum and rotate it for 100 Times. Remove the tablets from drum , remove any loose dust from them and weight them accurately. The friability test is run once only unless the results are difficult to interpret or if the weight loss is greater than the targeted value in which case the test is repeated twice and the mean of the three test is determined. Maximum loss weight from a single test or from a mean of three tests not greater than 1.0% is acceptable most of the products.

After tumbling if most of the tablets obviously cracked, Chipped, Cleaved or broken tablets are present in the sample then the sample fail the test.

Calibration of Friability Test Apparatus :

RPM Calibration :

Timer Calibration :